Your shopping cart is empty!

MENU

- +

-

Categories+

- Blog +

- Contact Us +

- Login +

- Register +

Which works better – a traditional oil-sealed vacuum pump or an oil-free diaphragm vacuum pump? To determine which one best suits your particular application, here’s a more in-depth look on what each one has to offer.

Which works better – a traditional oil-sealed vacuum pump or an oil-free diaphragm vacuum pump? To determine which one best suits your particular application, here’s a more in-depth look on what each one has to offer.

Vacuum Pumps in the Lab

Historically, older laboratories are equipped with a central vacuum system. However, since central vacuum systems are installed during construction, modifying them to suit your application can be quite a challenge. Taking into consideration the inflexibility of the design along with the high risk of cross-contamination between vacuum applications, limited capabilities and the various sustainability issues associated with the system, today laboratories choose to do without it and installed individual vacuum pumps instead.

Choosing a Vacuum Pump: A Quick Guide

Basically, there are two main types of vacuum pumps used in the laboratory – the oil-sealed vacuum pump (also known as rotary vane pump or oil-lubricated pump) and the oil-free or dry pump (e.g. diaphragm, piston and scroll pumps). So, which should you choose? Here are some things you may need to consider to make sure you come up with the right choice.

Oil Sealed Vacuum Pump

If you need maximum reliability and efficiency under the most difficult conditions, an oil sealed vacuum pump may be just the thing you need. These pumps provide a deeper vacuum (up to 10-3 Torr) than dry vacuum pumps (less than 10-1 Torr) and are ideal for freeze drying and molecular distillation applications. Here are some of the advantages of an oil sealed vacuum pump system:

On the downside, oil-sealed vacuum pumps require regular oil changes to ensure proper functioning and extend the life of the unit. In addition, the presence of oil increases the risk of contamination (i.e. when the oil seal and the process vapours come into contact) and the disposal of the contaminated waste oil can be a bit costly.

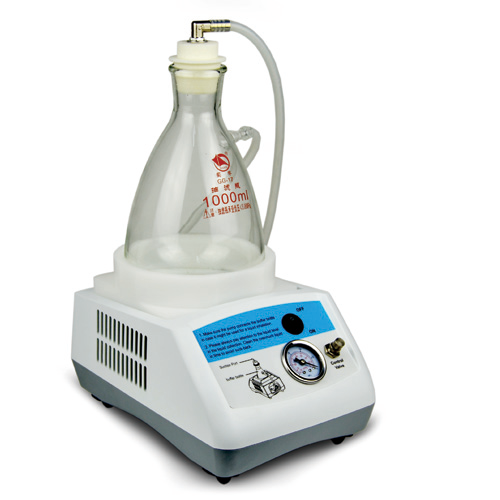

Diaphragm Vacuum Pump

Oil-free vacuum pumps such as the diaphragm pump may be more expensive than the traditional oil-sealed vacuum pump but they require little to no maintenance and do not need regular oil changes. There is also no risk of contamination since evacuated gas is readily recovered after being released from the pump. This means you don’t even need to worry about installing cold traps (except for extreme conditions). These systems usually have PTFE-coated components making them ideal for acid or solvent applications.

However, diaphragm pumps also come with some disadvantages. For one, they cannot handle large slugs of liquid and particulates and can be quite loud.

So, which vacuum pump is better? Well, this really depends on your particular application, needs (e.g. vacuum depth, pumping speed, energy consumption) and situation (e.g. budget, objectives, sustainability) so consider these things before choosing a vacuum pump for your lab.

Leave a Comment