Your shopping cart is empty!

MENU

- +

-

Categories+

- Blog +

- Contact Us +

- Login +

- Register +

Solvent evaporation or removal is a vital process used in a wide range of applications both in the laboratory and in industrial settings. It is especially helpful when preparing and concentrating samples for analysis and in preserving and/or modifying solutes. This process is also useful in a number of chemical syntheses, particularly when the solvent used in generating an intermediate needs to be eliminated due to its incompatibility with the succeeding reaction steps.

Solvent evaporation or removal is a vital process used in a wide range of applications both in the laboratory and in industrial settings. It is especially helpful when preparing and concentrating samples for analysis and in preserving and/or modifying solutes. This process is also useful in a number of chemical syntheses, particularly when the solvent used in generating an intermediate needs to be eliminated due to its incompatibility with the succeeding reaction steps.

However, please note that there is no single solvent removal technique that can accommodate the range of applications. Thus, a variety of methods (i.e. evaporation, lyophilization or freeze drying, dialysis or solvent exchange, etc.) are commonly used to facilitate the solvent removal process.

Solvent Removal 101: Understanding the Process

During solvent removal, energy (usually in the form of heat) is applied to vaporize the liquid solvent. Different heating systems (e.g. electrical heating blocks, lamps or low temperature steam) are used to supply the energy required to induce solvent vaporization. As the solvent evaporates, it leaves a concentrated, solvent-free product behind.

While solvent removal can be accomplished through a number of methods, the underlying principle remains the same – heat and pressure must be applied to effect a change of state (i.e. liquid to gas). But since the temperature by which boiling or evaporation occurs is highly affected by pressure, you can adjust the conditions (e.g. apply vacuum to allow vaporization to take place at a lower temperature or supply heat energy to frozen samples at low pressure to facilitate the sublimation of the solvent) to suit the intended application.

Note: Different systems remove solvents under different conditions and leave long-term effects on the end product. As such, determining the appropriate process for the specific sample is considered to be of vital importance.

Solvent Removal by Evaporation

Solvent removal by evaporation is ideally used for concentrating non-volatile solutes. In this method, the sample can either be boiled or inert nitrogen gas is used to draw the liquid out.

However, while boiling can remove some solutes, many (e.g. proteins and other biological samples) are highly sensitive to heat and can be damaged in the process. Additionally, the movement of the molecules during the process may lead to sample loss (i.e. the solution may splatter on the side walls of the glassware) or cross-contamination, especially when several tubes are placed together in close proximity.

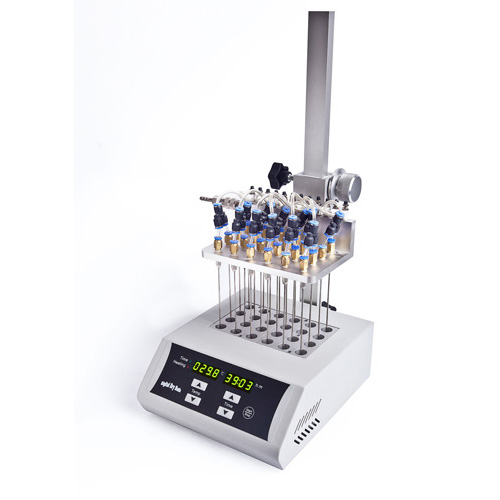

Alternatively, solvent removal by evaporation can also be effected by using a nitrogen blow down evaporator. This approach uses heat and directs dry, pure nitrogen gas onto the solvent to evaporate moisture from the sample. This decreases the density of vapor phase solvent molecules and tips the vapor-liquid phase equilibrium. As a result, more liquid is drawn into the vapor phase, increasing the rate of evaporation.

Nitrogen evaporators are ideally used for sample preparation prior to analysis and are used in many industries (e.g. food, biotechnology, environmental sciences, analytical chemistry, etc.). Since a nitrogen blow down evaporator requires higher heat input compared to a vacuum evaporator, it is generally used for volatile solvents. It is also suitable for samples that are not easily damaged at moderate temperatures.

Most laboratories make use of liquid nitrogen supplied from a high-pressure gas cylinder, a liquid nitrogen tank, a or a Dewar for this purpose. Although these provide satisfactory results, using a nitrogen generator is more advisable since it is safer, more cost-effective (low operational cost and does not entail any hidden costs), requires minimal maintenance and has low environmental impact.

Leave a Comment