Your shopping cart is empty!

MENU

- +

-

Categories+

- Blog +

- Contact Us +

- Login +

- Register +

There are three ways by which macromolecules can be transferred from SDS-PAGE or native gels to the appropriate nitrocellulose, PVDF or nylon membrane for subsequent detection. It can be done through diffusion blotting, vacuum blotting, and electroblotting or electrophoretic transfer. However, for the purpose of this article, we will be focusing on wet and semi-dry electroblotting methods since they are significantly faster and more efficient compared to the other methods. This article will also give you an overview of what is involved in these techniques, their key differences and when should you use one over another.

There are three ways by which macromolecules can be transferred from SDS-PAGE or native gels to the appropriate nitrocellulose, PVDF or nylon membrane for subsequent detection. It can be done through diffusion blotting, vacuum blotting, and electroblotting or electrophoretic transfer. However, for the purpose of this article, we will be focusing on wet and semi-dry electroblotting methods since they are significantly faster and more efficient compared to the other methods. This article will also give you an overview of what is involved in these techniques, their key differences and when should you use one over another.

Electrotransfer Systems for Western Blotting: How Do They Work?

No matter what electroblotting technique you use, your success will depend on one thing – the electophoretic mobility of your proteins. Here’s what happens during the process: when an electric field is applied across the transfer medium, the proteins are transferred from the polyacrylamide gel onto the membrane, creating an exact copy of the protein separation pattern seen in the original gel.

Wet Electroblotting (Tank Transfer)

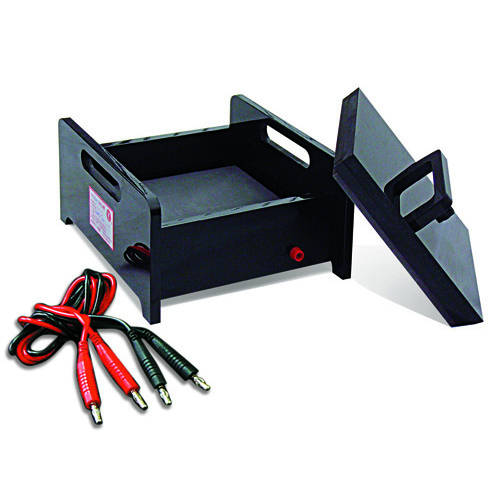

Wet electroblotting, also known as tank transfer system, has been used in protein laboratories all over the world for a very long time. In this method, the gel is equilibrated in transfer buffer (usually Tris-glycine buffer) before being placed in the transfer sandwich (gel and transfer membrane sandwiched between two sheets of filter paper). The transfer sandwich is then cushioned with pads, pressed together with a support grid and placed vertically in a tank filled with transfer buffer.

After loading the transfer sandwich in the wet tank apparatus, constant current is applied (30 V or 1 A) in as little as one hour to overnight to elute the proteins from the gel and transfer them to the membranes. To prevent overheating the buffer, most transfers use an ice pack to dissipate the heat or are performed in a cold room. Bringing the transfer time down to 30 minutes is also possible, but you need to apply a higher voltage or current (up to 200V or 1.6 A) and use an appropriate cooling system to prevent overheating.

Generally, wet transfer works best for lower molecular weight proteins. Thus, it is possible to achieve transfer efficiencies of 80% to 100% when working with proteins between 14 to 116 kDa. Better transfer efficiencies can also be achieved by increasing transfer time, but it may increase the risk of over-transfer or stripping of the proteins through the membrane, especially if you are working with lower molecular weight proteins (i.e., less than 30 kDa) and using membranes with a pore size of 0.45 um.

When doing wet transfers, please take note of the following:

For semi-dry transfers, the transfer sandwich is placed horizontally between the two plate electrodes in the transfer apparatus. A constant current (0.1 to 0.4 A) or voltage (10 to 24 V) is applied for 10 minutes to one hour. It is possible to get transfer efficiencies of 60% to 80% for proteins between 14 and 116 kDa.

If you want to improve the speed of transfer, you need to maximize the current passing through the gel by a) limiting the amount of buffer to that contained in the transfer sandwich, b) cutting the membrane and filter paper sheets to the exact gel size (i.e., no overhang) and c) thoroughly equilibrating the gel and filter paper in the transfer buffer. In some cases, using an extra thick filter paper helps to improve the transfer rate since it can retain more transfer buffer. You can also reduce transfer time to approximately 7 minutes by using methanol-free buffers and high current power supply.

When doing semi-dry transfers, please take note of the following:

Why Should You Choose One Over the Other?

Generally, if you are after higher efficiency, use the traditional wet transfer but if you want convenience and speed, go for semi-dry electroblotting. Wet transfer systems are ideal for most routine protein work, no matter what the protein size, and offer the most flexibility in terms of blotting times, voltage settings and cooling options. On the other hand, semi-dry transfer systems are easier to set-up, require less buffer and provide high throughput results. They are also ideally used for transfers that do not require extended times and those that use discontinuous buffer systems.

Leave a Comment